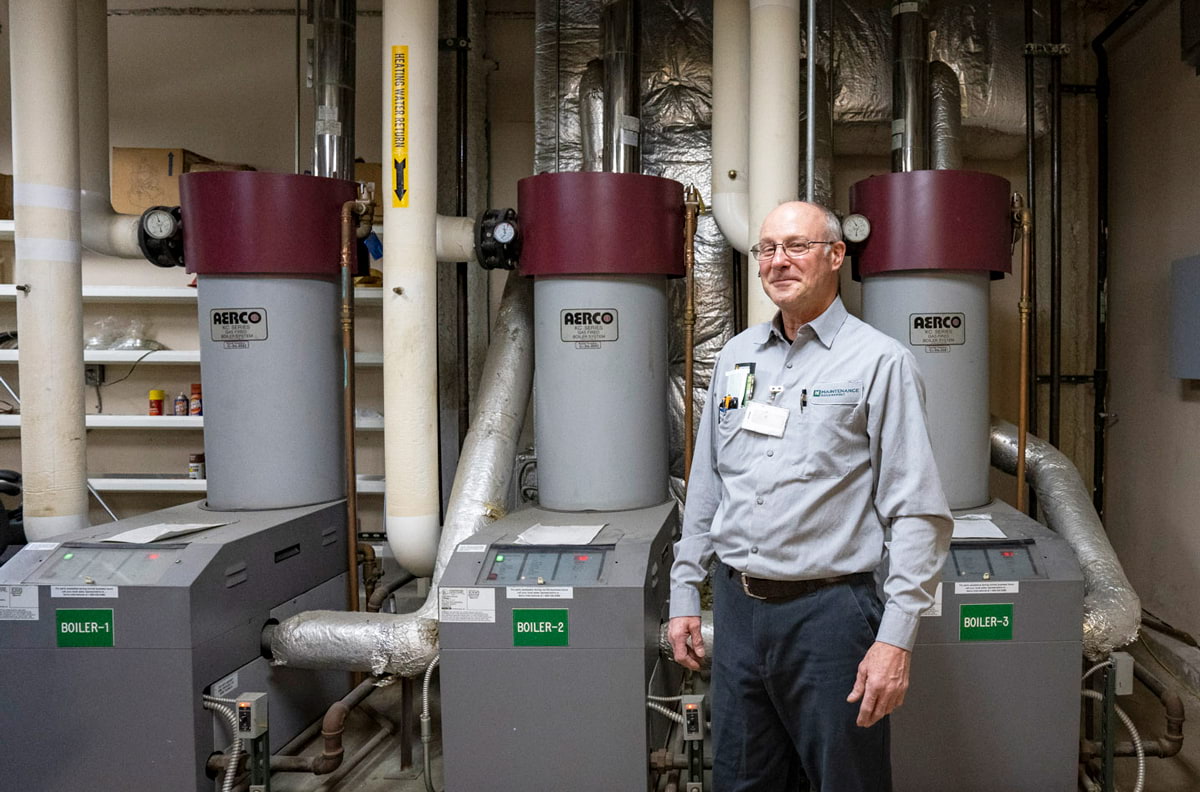

One of the keys to providing outstanding maintenance services is experience. Nothing expands the depth and breadth of a technician’s expertise faster or more completely than on-the-job training. One of our team members can attest to that. Kevin has now been with Maintenance Management for 40 years!

We recently sat down with Kevin to talk about this impressive milestone and how he got to where he is today.

Wow, 40 years! Does it feel like you’ve been with us for four decades?

It’s beginning to. Ten years ago, it didn’t feel like I’d been with the company for 30 years, but now it’s beginning to feel like 40. Maybe that’s because I’m starting to feel my age. But it’s been a good 40! I’ve had a great time and can honestly say I’ve enjoyed every day!

What made you apply for your first job at Maintenance Management?

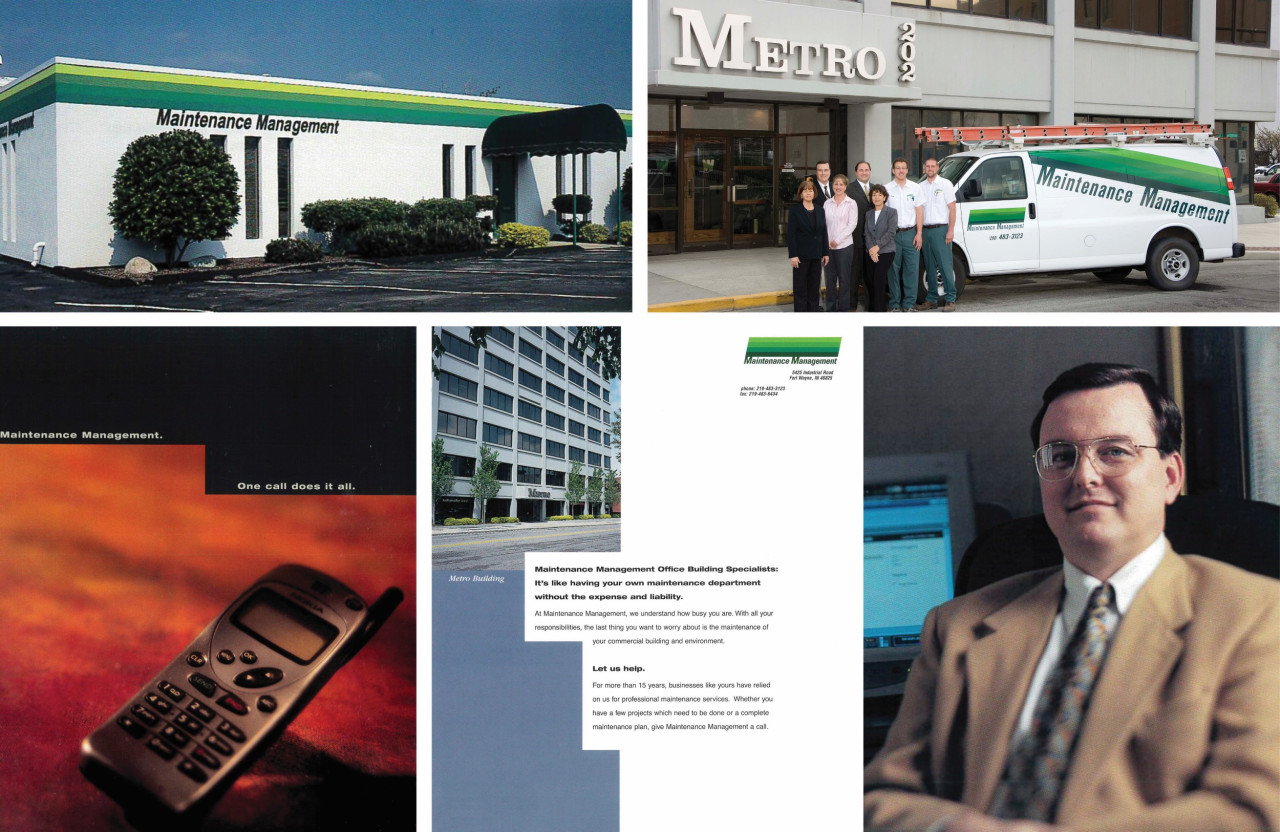

I actually didn’t have to apply. At the ripe, old age of 18 I already had a certificate from vocational school for Building & Industrial Maintenance and was working part time at a downtown parking lot where I parked cars and took money. Lowell Griffin, one of the founders of Sturges, Griffin, Trent & Company, parked his car there daily and noticed the way I was motivated and hustled around. He said, “You need to go talk to Greg Petras.” Greg, one of the original founders of Maintenance Management, also saw what Lowell saw in me and hired me on the spot. I was a good fit for the position they were looking to fill. Both Greg and Lowell played a major part in me getting this job and I am very thankful. I really lucked into this job, and it’s worked out well for 40 years!

Do you remember your first day at Maintenance Management?

Yes, I do. It was mostly walking fast behind Greg. We took care of five to seven buildings all around a two-block square downtown. Everything was in walking distance. It was a fast walk as we toured all of the buildings that we took care of. I learned how to walk fast because he was a bit taller than me. That was my first day: Learning where I would be working and what I was going to be doing.

Back then, there were only two employees and Greg who did everything from air conditioning to plunging toilets. I did a lot of lightbulb changes and repairing locks, and I followed Greg around to learn about air conditioning issues. Before long he said, “You’ve seen me do this three times, you can do it now.” It was a quick evolution, and I stayed busy. I would walk up and down the block to respond to one call after another.

I’m remembering other fun details from the early days. One time, Greg went to Chicago for a weekend and left me with his service van, because I didn’t even have a truck yet. I parked it in front of my apartment complex in a way that blocked the driveway of a vacant house. But someone was moving in that Saturday morning and had his van towed because it was in the way. So, I got up in the morning and realized his van was gone with all of his tools! I had to figure out how to explain that to him on Monday morning. Thankfully, he didn’t fire me.

How has your job changed over the years?

In the early years, I did a lot of fixing locks and changing lightbulbs. But soon I advanced to making complicated HVAC system repairs and working on boilers to chillers. It’s kind of like I moved from first grade math to algebra over time.

What’s one of your favorite memories of the last 40 years?

That’s tough. There are so many. Maintenance Management allowed me to go to Vegas a few times as work anniversary gifts, and I got to go to a heavy weight championship fight. You don’t get to see that every day! I got to travel to a control manufacturing facility in Chicago to learn programming and installation in a month-long training. There was also training in control systems electronics programming in Wisconsin for a month, and more training and an HVAC seminar in Florida for a month. And just a few years ago, I was sent back to Vegas for a one-week HVAC seminar. So, I’ve gotten to see and learn a lot of things thanks to Maintenance Management.

And, of course, I have some great memories from getting together at company gatherings to have fun and visit with everyone.

Do you have a favorite project you’ve worked on? Can you describe it and what made it memorable?

I worked at a very large insurance office in town when it was five of us on a large project that went on for 9-10 years. That was a great experience for me. I was supervising a crew and also doing HVAC work, so it was challenging—a new adventure every day. We had a really well-rounded crew out there, and we did everything from data cabling and telephone connections, to full building maintenance. I was responsible for all of the work orders in the system, which put a lot more administrative responsibility on me. I wasn’t used to that, but I enjoyed the opportunity.

What advice do you enjoy giving new technicians?

Embrace every day as a new adventure. In maintenance, no two days are alike, so you’ve got to take it as it comes.

I also can’t stress ladder safety enough. Leave the horseplay for the horses, I say. Protect yourself, because nobody else will. Safety is a top priority. Of course, protecting yourself is easier said than done. I’ve been injured multiple times over the years—sometimes because of carelessness and sometimes it just happens. I’ve had a fractured heel and other broken bones, plus several surgeries. This can be a hazardous job sometimes, so I can’t stress safety enough.

What’s your favorite aspect of the culture at Maintenance Management?

Maintenance Management has always been a caring company, both with employees and customers. I love getting together for things like summer events and Christmas parties. It makes it clear that we all have each other’s back if something goes wrong.

It’s a good feeling knowing that we work for a great company. The company has been there for me in many ways over the years, including offering any needed time off for family health issues, so I could always be with my loved ones in times of stress.

And if management has a sense that something’s wrong, they always ask. For example, in the late 80s, when I was working both as a manager and in the field, they noticed my stress level was pretty high and sent me to Florida for a week-long cooling tower seminar, which also served as a getaway trip for me.

What were some lessons that you learned from some of your past mentors?

I learned to look beyond the things in front of you. There’s usually something beneath the surface that’s causing the issue. Don’t just change out the bad part. You need to figure out why it failed in the first place. Don’t just take the simple solution. Make sure you look over the whole problem before you walk away.

How important do you feel it is to have trade school as an option out of high school instead of just attending a college or university? How is this imperative to the future of the industry?

It’s very important. If everyone sat behind a desk all day, nothing would get built or fixed. What would the world look like?! It’s no secret that there’s a shortage of tradesmen. Unfortunately, skilled labor is not always looked at as a good career option even though it can pay very well. Plus, you receive a daily reward when you build, fix, or install something. It’s a reward when you can see your hard work pay off.

We need people who can fix, build, and install things. If nobody constructs the building for you to put your desk in, you won’t have a place to work. I’m an example of the benefits of attending a trade school. It got me a job right away and I’ve been good ever since. Trade school has provided me with a 40-year (and counting) career. I would love to see more people get into the trades out of high school.

How many people do you know that get a great education, but can’t apply it to daily life? An electrician is always in demand. When my son was in high school, he received a very basic education in shop class. When I was in school, we had 2-3 years of woodworking class alone before we could get into metal shop class if you wanted to take it. These are very valuable skills that are becoming more of a necessity. More young people should consider trade school as an option out of high school.

What do you foresee as the biggest future challenges in the HVAC field?

Being able to keep up with the technology changes implemented due to greenhouse gases, global warming, and efficiency ratings. Things are changing very fast. Between regulations and technology, it’s harder and harder to keep up.

You know things are getting more complicated when they take spaceship technology and put it into an air conditioner! There are bigger circuit boards in some of these air conditioners and chillers now than there are in a computer. The technology is advancing very quickly and increasing the chances for failure because the service industry isn’t properly prepared for these advances and don’t know how to properly take care of these systems. Which is another reason for going to trade school, seminars, and training to stay on top of these constantly changing technologies.

The systems that I installed 30 years ago are extinct now because of these changing technologies. The system may be extinct, but the basic setup is still the same. They are doing essentially the same thing, just with more complications.

What do you enjoy doing away from work?

I like mowing my yard. I grab a nice, cold beer and away I go. I also enjoy gardening and mushroom hunting in the spring, camping, fishing, and kayaking. Woodworking is another hobby of mine. I make footstools, wooden spoons, and wall plaques with deer antlers. But footstools are my favorite. One footstool took me three years to finish! I don’t sell them, but will make them for my grandkids. I enjoy working with cherry and walnut. I’m looking forward to doing more woodworking as I near retirement.

Any additional thoughts?

Maintenance Management has been good to me, and the people I work with are great. I’ve truly enjoyed these 40 years, but there’s more to come. I still have several years before retirement.

Congratulations, Kevin, and Thank You!

It takes a special type of person to face new maintenance and repair challenges every day for 40 years and always have a positive attitude and a commitment to doing things the right way. We’re fortunate to have you on our team, Kevin, and so are our customers.

We wish you the best as your adventures at Maintenance Management continue, and a very happy retirement when that day comes!